AugaOne™

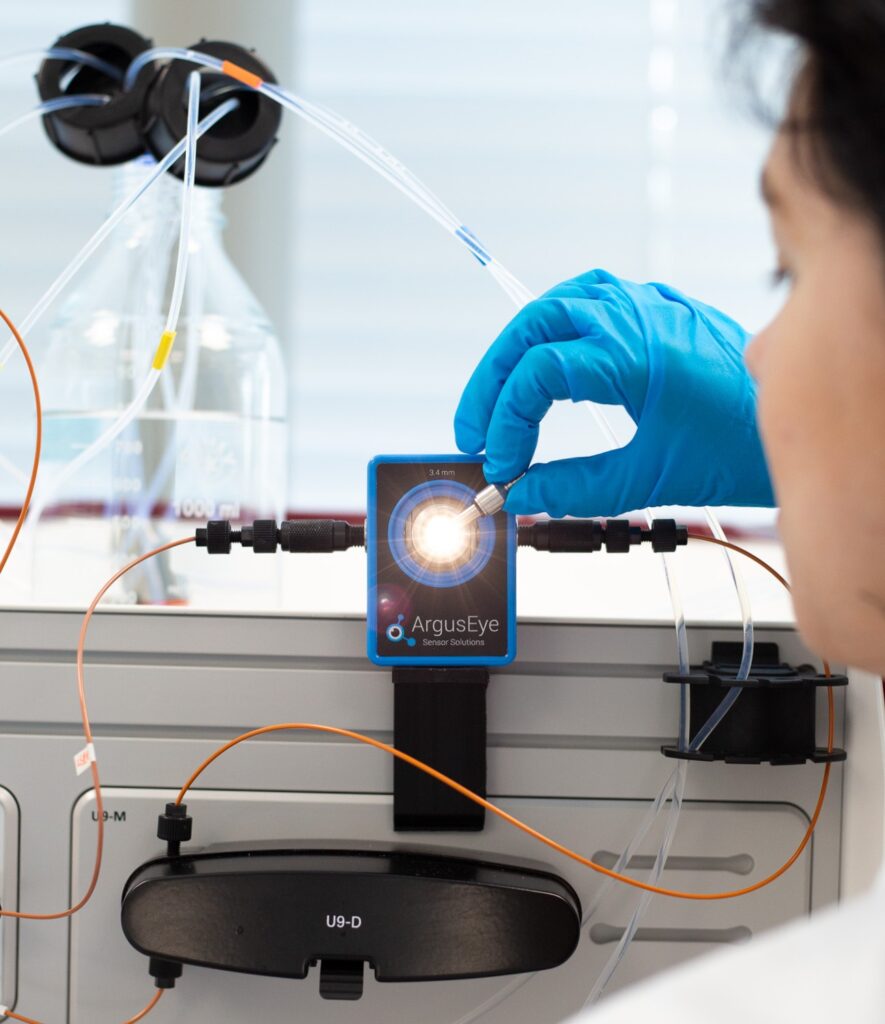

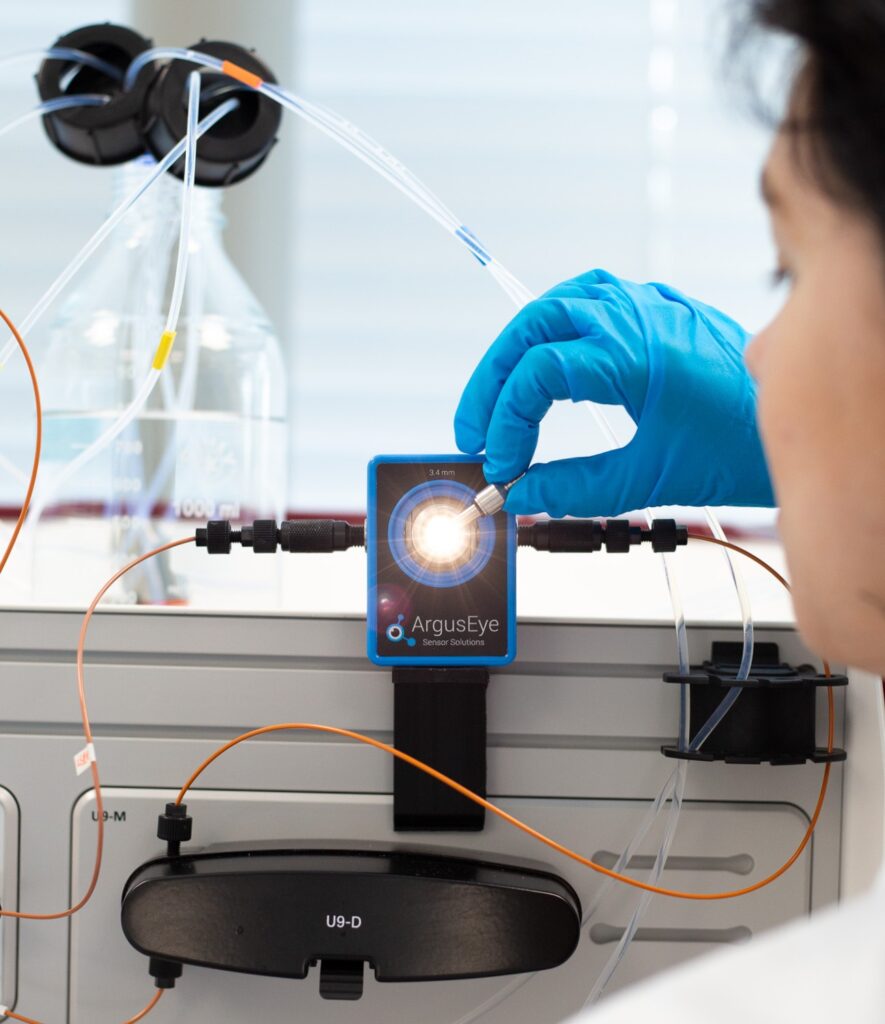

AugaOne™ is the first plug-and-play, in-line sensor system for real-time detection and measurement of specific proteins during chromatography purification in process development. Powered by proprietary Localized Surface Plasmon Resonance (LSPR) technology, it delivers label-free, high-sensitivity measurements directly in the flow without the need for sample pretreatment.

Designed for downstream bioprocess development, AugaOne™ provides automated, specific in-line data with minimal setup. It integrates seamlessly with existing chromatography systems, reduces lead times, and enables actionable insights from day one.

AugaOne™

AugaOne™ is the first plug-and-play, in-line sensor system for real-time detection and measurement of specific proteins during chromatography purification in process development. Powered by proprietary Localized Surface Plasmon Resonance (LSPR) technology, it delivers label-free, high-sensitivity measurements directly in the flow without the need for sample pretreatment.

Designed for downstream bioprocess development, AugaOne™ provides automated, specific in-line data with minimal setup. It integrates seamlessly with existing chromatography systems, reduces lead times, and enables actionable insights from day one.

AugaOne™

AugaOne™ is the first plug-and-play, in-line sensor system for real-time detection and measurement of specific proteins during chromatography purification in process development. Powered by proprietary Localized Surface Plasmon Resonance (LSPR) technology, it delivers label-free, high-sensitivity measurements directly in the flow without the need for sample pretreatment.

Designed for downstream bioprocess development, AugaOne™ provides automated, specific in-line data with minimal setup. It integrates seamlessly with existing chromatography systems, reduces lead times, and enables actionable insights from day one.

Replace time-consuming off-line analyses with in-line analytics, thereby eliminating the need for sample treatment procedures.

Selective detection of IgG within complex sample matrices using specific ligands.

Sensor signals are captured at one-second intervals, enabling real-time analytical measurements.

With its add-on capability, and quick, straightforward installation, the system offers a minimal entry barrier and can be used from day one.

Unique stability in providing reliable and reproducible measurements under changing bioprocess conditions. Delivers immediate resource savings, including over 20% less affinity resin usage, reduced buffer and energy consumption, and a smaller environmental footprint.

Replace time-consuming off-line analyses with in-line analytics, thereby eliminating the need for sample treatment procedures.

Selective detection of IgG within complex sample matrices using specific ligands.

Sensor signals are captured at one-second intervals, enabling real-time analytical measurements.

With its add-on capability, and quick, straightforward installation, the system offers a minimal entry barrier and can be used from day one.

Unique stability in providing reliable and reproducible measurements under changing bioprocess conditions. Delivers immediate resource savings, including over 20% less affinity resin usage, reduced buffer and energy consumption, and a smaller environmental footprint.

Built on proprietary LSPR-based fiber optic detection, AugaOne™ utilizes single-use, ligand-functionalized sensor chips to achieve sub-μg/mL sensitivity in complex downstream matrices. The system integrates seamlessly with existing chromatography setups and supports real-time Process Analytical Technology (PAT) implementation through OPC-compatible software.

The hardware consists of a compact optical unit with integrated LED and CMOS detector, stainless-steel flow cells (0.01–250 mL/min), and robust sensor chips functionalized with Protein A, G, or L. The chips provide specific, reproducible binding with minimal signal variation and allow for multi-cycle use through on-chip regeneration within a single process run.

The dedicated software enables automated signal acquisition for real-time monitoring with a sampling interval of about 1 second. Through OPC DA/UA integration, it efficiently collects and displays data from ÄKTA purification system detectors, such as UV absorbance, conductivity, and pH, alongside data from our sensor for a complete process overview.

Certified with CE-marking and validated in GMP-like environments, AugaOne™ reduces lead times, manual work, and analytical overhead making it a critical enabler for modern downstream process development.

Sensor Chips

Flow Cell

Optical Unit

Optical Unit

Dimensions:

Weight:

Light source:

Minimum light source lifetime:

Detector:

Temperature range:

Power supply:

Data transfer:

W205 x D177 x H66 mm

1.5 kg

Warm white LED 3000 K

10 000 h

CMOS

10–30 °C

5 V DC @ 700 mA

USB3

Flow Cell

Dimensions:

Weight:

Material:

Design:

Flow rate:

Dead volume FC34 / FC15:

W50 x D24 x H71 mm

304 g

Medical grade stainless steel

Single channel

0.01-250 mL/min

213 µL / 82 µL

Application Notes

Brochures & Data Sheets

Presentations

Scientific Publications

Built on proprietary LSPR-based fiber optic detection, AugaOne™ utilizes single-use, ligand-functionalized sensor chips to achieve sub-μg/mL sensitivity in complex downstream matrices. The system integrates seamlessly with existing chromatography setups and supports real-time Process Analytical Technology (PAT) implementation through OPC-compatible software.

The hardware consists of a compact optical unit with integrated LED and CMOS detector, stainless-steel flow cells (0.01–250 mL/min), and robust sensor chips functionalized with Protein A, G, or L. The chips provide specific, reproducible binding with minimal signal variation and allow for multi-cycle use through on-chip regeneration within a single process run.

The dedicated software enables automated signal acquisition for real-time monitoring with a sampling interval of about 1 second. Through OPC DA/UA integration, it efficiently collects and displays data from ÄKTA purification system detectors, such as UV absorbance, conductivity, and pH, alongside data from our sensor for a complete process overview.

Certified with CE-marking and validated in GMP-like environments, AugaOne™ reduces lead times, manual work, and analytical overhead making it a critical enabler for modern downstream process development.

Sensor Chips

Flow Cell

Optical Unit

Optical Unit:

Dimensions:

Weight:

Light source:

Min. light source lifetime:

Detector:

Temperature range:

Power supply:

Data transfer:

W205 x D177 x H66 mm

1.5 kg

Warm white LED 3000 K

10 000 h

CMOS

10–30 °C

5 V DC @ 700 mA

USB3

Flow Cell:

Dimensions:

Weight:

Material:

Design:

Flow rate:

Dead vol. FC34/FC15:

W50 x D24 x H71 mm

304 g

Medical grade stainless steel

Single channel

0.01-250 mL/min

213 µL / 82 µL

Application Notes

Brochures and Data Sheets

Presentations

Scientific Publications

Webinars

Fill out the form below, and one of our specialists will get back to you promptly with a personalized quote.

Would you like to book a demo? Contact us using the form below and we will be sure to get back at you as soon as possible.

You can also email us at info@arguseyesensors.com

Do you have questions about our products, applications or technology? Contact us using the form below and we will be sure to get back at you as soon as possible.

You can also email us at info@arguseyesensors.com